OUR SERVICES

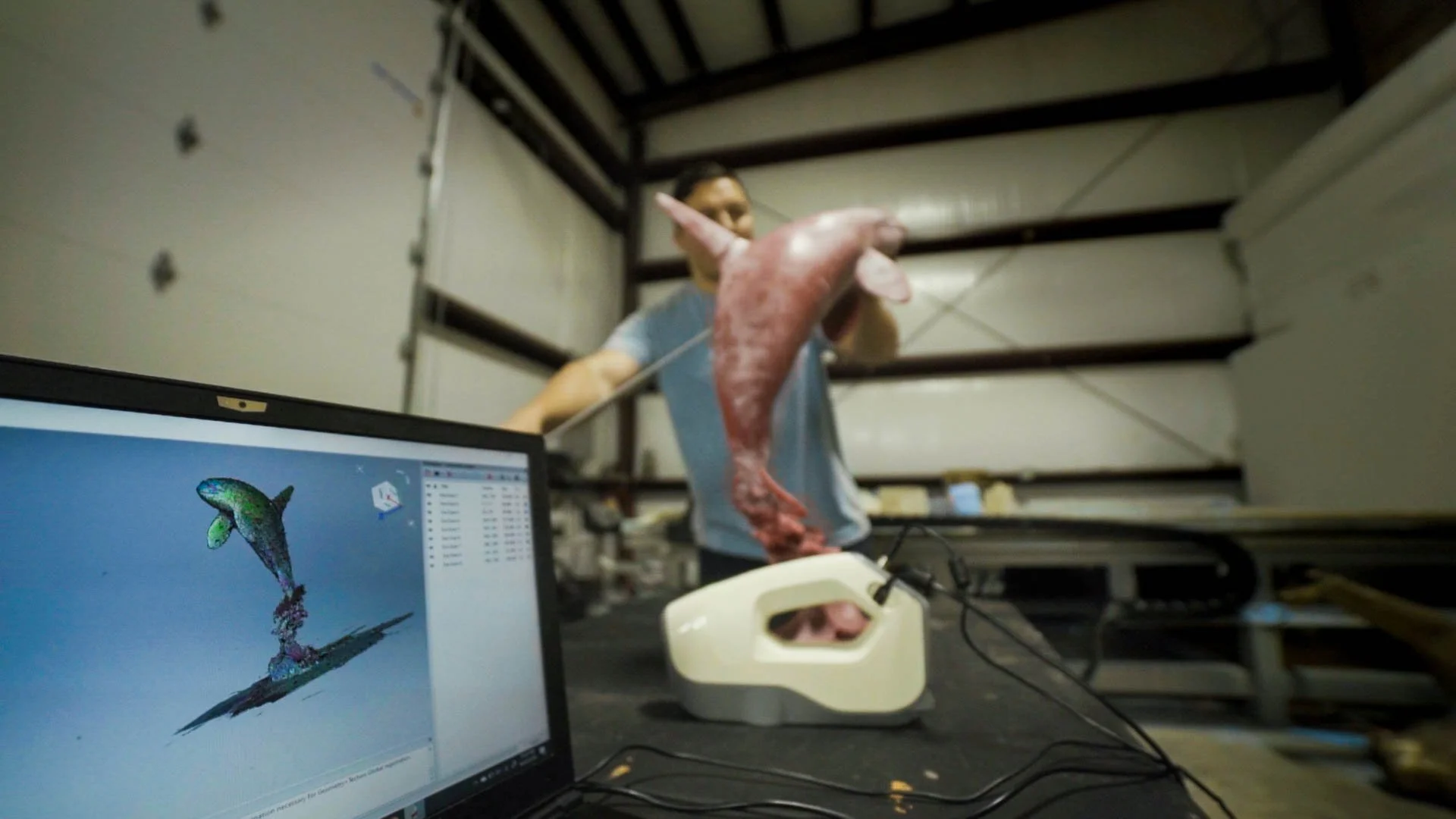

3D Services

3D scan a loved one or a sculpture to enlarge

3D modeling and printing services

Take 3D file from your computer all the way to patina’ed bronze

Lost Wax Casting

Lost Wax Casting from an existing mold or new mold we create for you

Post cast metal tooling and cleaning

Patina and basing

Repair

On location patina and metal tooling repair

Dropped off or shipped sculptures repaired at our Oregon based foundry

OUR STORY

Rip Caswell started Firebird Bronze after 20 years of sculpting experience. He found it hard to guarantee timelines on his sculptures to his clients and taking the foundry portion of his work into his own hands allowed him to ensure the highest level quality and timeliness of his pieces for his clients. As sculptor friends saw the quality produced from his foundry more and more artists jumped on board, using Firebird as their primary foundry.

Rip’s son Chad started 3D modeling and printing in 2013, seeing an opportunity to use new 3D scanning and printing to simplify modeling and wax casting. Rip and Chad quickly realized adding in these new tools allowed Firebird to iterate on projects with clients and complete projects faster than ever before.

Today, Firebird’s ethos of timeliness and quality hasn’t change but now Firebird works with a large group of clay sculpture artists to cast and finish their pieces, 3D artists to print and cast their pieces and individuals and companies to make their custom sculptures dreams reality.